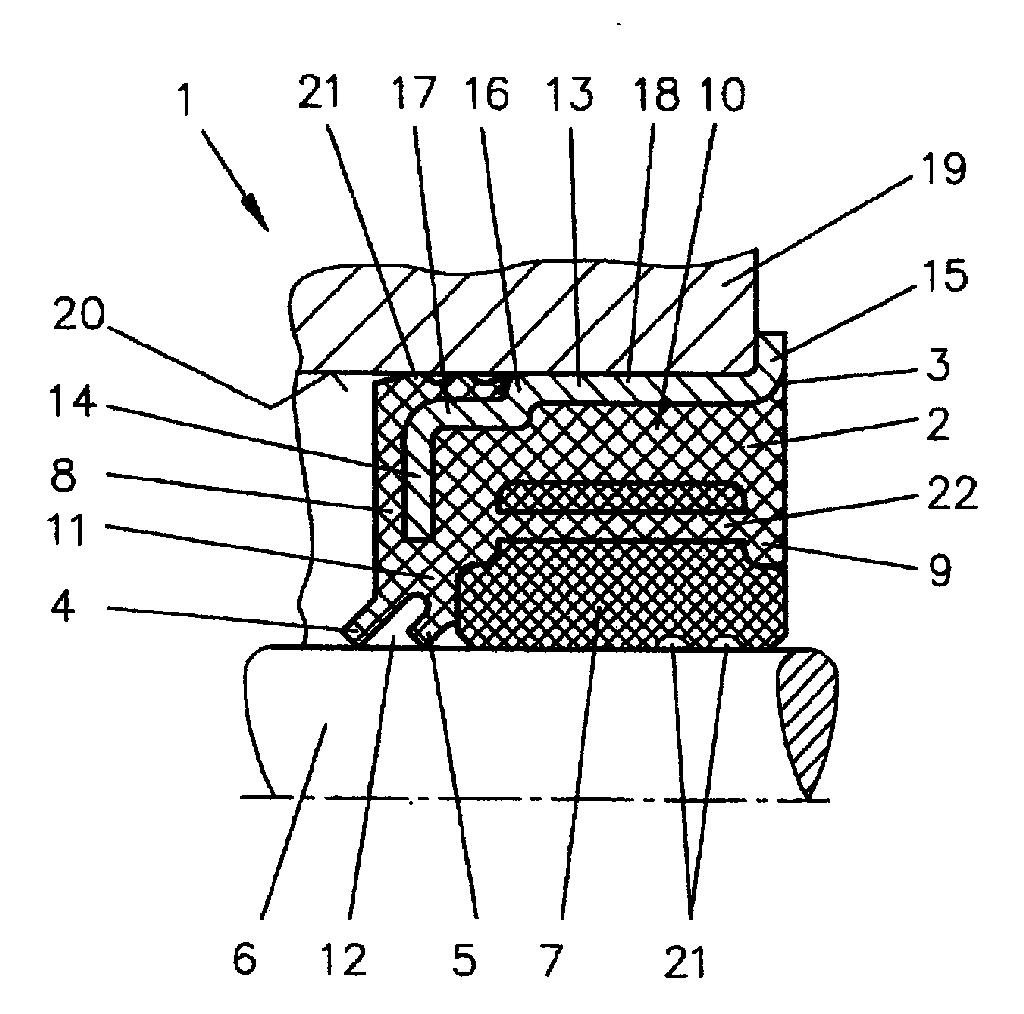

The second is that this same complexity can cause labyrinth seals to be more expensive than other sealing options. The first is that the complexity of the design may require more physical space than other seals, which can be difficult to manage depending on your application. While labyrinth seals offer the best of both contact and non-contact seals, there are some potential downsides. As such, labyrinth seals offer the sealing capabilities of a contact seal while limiting added friction like a non-contact seal. In addition, it can fend off contaminants and prevent leakage without contact the inner ring. The complexity of a labyrinth seal allows it to provide excellent sealing capabilities. The two pieces interlock and create a thin, grooved path that is long and difficult for substances to escape or penetrate the bearing. Labyrinth seals are composed of multiple pieces – one that remains stationary and another the rotates with the system. The idea of a labyrinth seal is to prevent leakage and contamination by creating a difficult path for both substances to follow. However, the lack of contact with the inner bearing produces less friction, which can prevent overheating and other potential issues.Ī labyrinth seal is a type of bearing isolator that combines elements of contact and non-contact seals in a single component. This design provides protection against contaminants and leakage, but not to the same degree as a contact seal. While non-contact bearings do not touch the inner ring, they do feature a thin lip that rests adjacent to it. The main difference between the two is that non-contact seals are fixed to the outer ring and do not apply pressure to the inner ring of your bearing. Like contact seals, non-contact seals typically Buna-N and nitrile rubber parts bonded to a steel insert. Addition friction can also reduce the maximum speed of the bearing, so you’ll need to weigh your need for top-end sealing performance with the potential for wear and tear and loss of top speed. Added friction and heat can damage both the bearing and the seal and lead to premature part failure. The trade-off for premium sealing performance is that contact with the inner bearing produces both friction and heat. Contact seals also do an excellent job of sealing lubricants inside your bearing. This seal is designed to apply continuous pressure on a bearing’s inner ring, which creates the contact found in the seal’s name.īy providing direct contact with the inner ring, contact seals make it extremely difficult for contaminants like dust, dirt, and moisture to reach the inner parts of your bearing. Let’s break down the different types of seals available for your bearing products.Ī contact seal, also known as a lip seal, is a rubber part (typically Buna-N and nitrile) bonded to a steel insert. Both roles can help extend the life of your bearings, but it’s crucial to find the right seals for your parts.

Bearing seals actively do double duty, preventing contaminants from reaching the inside of your parts while keeping lubricants from leaking out. By preserving optimal performance reducing or eliminating oil mist spray and controlling temperature, moisture and contaminants, our bearing seals can ensure that your valuable equipment operates as intended for decades to come.A good bearing seal plays a key role in many bearings.

0 kommentar(er)

0 kommentar(er)